Ex Libris is the largest online bookseller in Switzerland and operates an online store with over 15 million items as well as 15 branches in German-speaking Switzerland. The range includes books, games, films and games for education and entertainment. Over one million people visit the online store every month and thousands of parcels leave the warehouse every day. Ex Libris was looking for a solution for the Dietikon logistics site to make the packaging process more efficient and ergonomic.

Before the BVS solution was introduced, employees in the dispatch department had to take the paper filling material required for packaging from individual containers scattered around the aisles and carry it to their workstation. This meant that employees had to bend down each time and walk countless distances during a work shift. The focus was therefore on reducing walking times and providing ergonomic and quick access to the paper filling material. The workflow was to be disrupted as little as possible during the conversion and access to the paper filling material was to be guaranteed at all times.

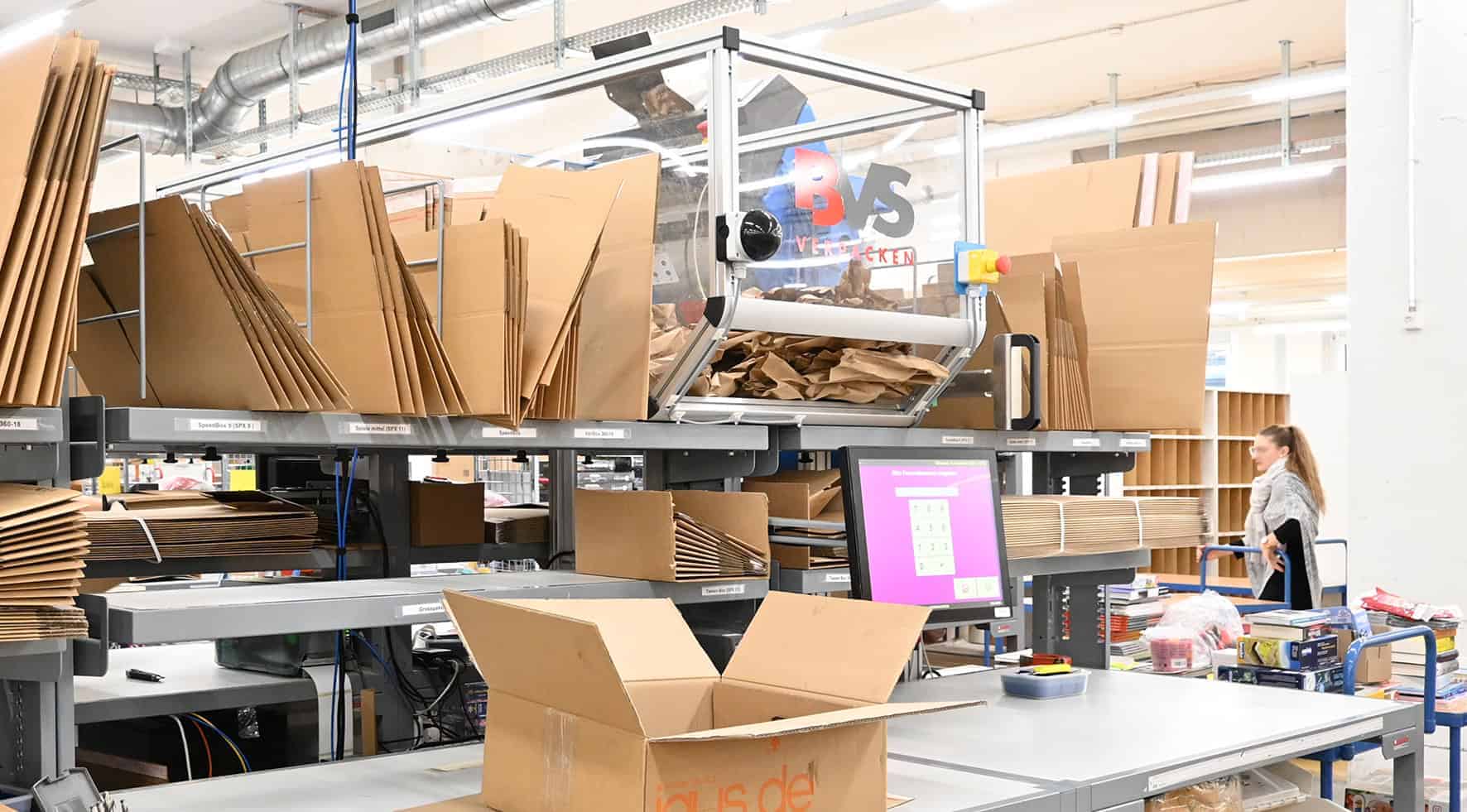

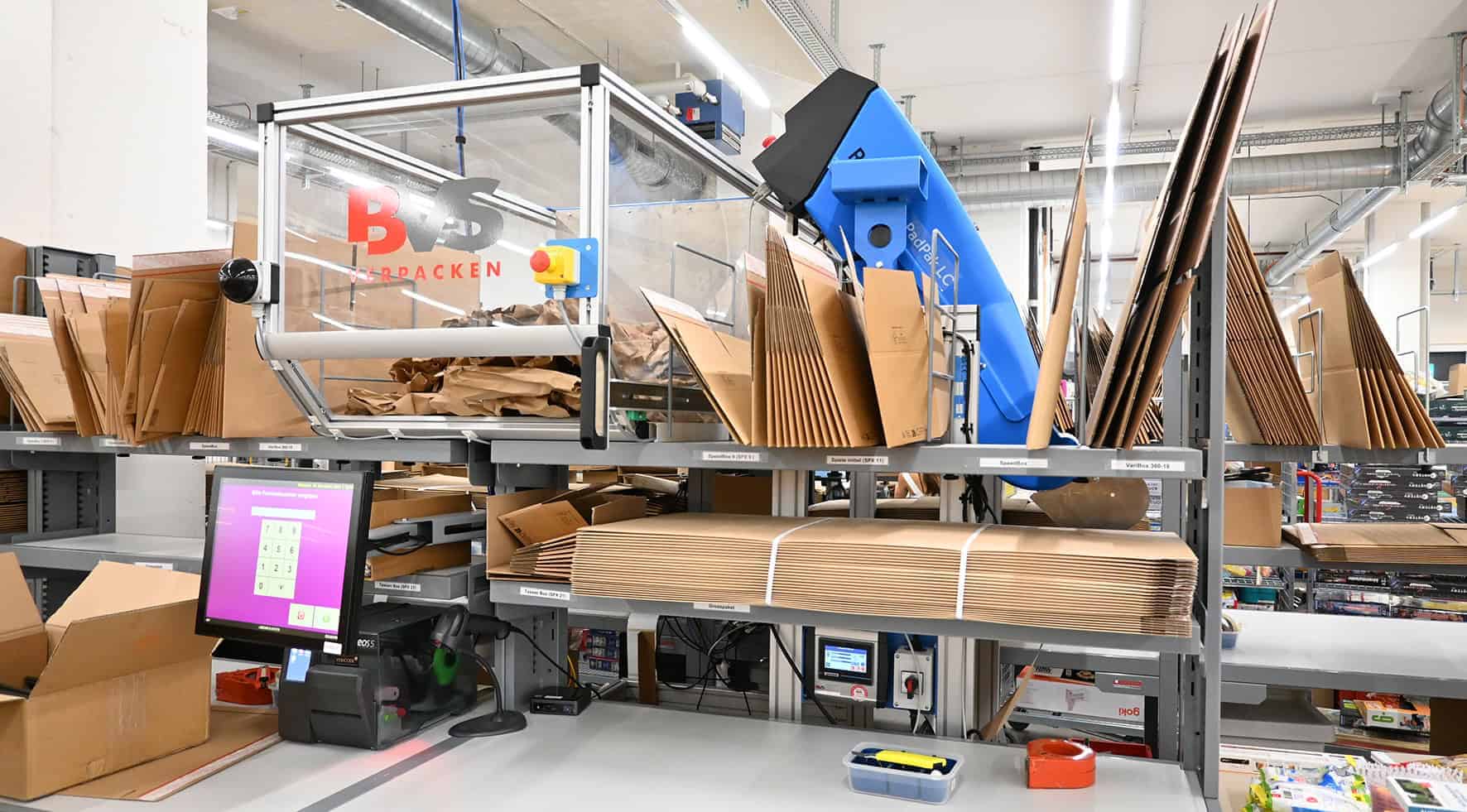

The idea of integrating paper filling systems into the packing tables was pursued from the outset in order to offer employees maximum convenience. The implementation now comprises 16 packing tables with four paper filling systems and four silos. The paper filling systems each hold 7.2 km of paper, which is automatically portioned into the silos provided for this purpose. From four packing tables, a centrally located silo with pre-packaged paper filling material can be accessed conveniently at working height, whereby the paper filling material can be diverted to the opposite workstations via a pusher.

The BVS solution has drastically reduced employee transit times, increased capacity and, thanks to access to the filling material at an ergonomic height at the workstation, reduced physical strain on employees and increased satisfaction. The elimination of the filling material containers also created more space in the aisles.

Packaging - As much as necessary,

as little as possible

BVS uses the NaturePak label for products that enable ecologically sound use, reduce CO2 emissions and generate less waste, regardless of the packaging material used.

Our strategy

Packaging made from recycled paper

Paper pays off for people and the environment in the long term. It is even better to use paper with a high recycled content. Recycled paper optimizes water and energy consumption and thus protects the environment and climate by reducing waste. Recycled paper offers a wide range of added value for all users.

Plastic packaging with recycled content

Polyethylene films are increasingly being produced with a proportion of recycled material, which - as far as technically possible - is being continuously increased. They are the most modern and safest quality packaging for all branches of industry. Due to their low density and excellent physical and mechanical properties, PE films have major advantages over paper, cardboard, metal and glass.

Please select your location: