The Swiss family business petZEBA has been delighting animal lovers in Switzerland for years with its high-quality pet food for dogs, cats and horses. But that's not all: the diverse range includes chews, cat sand, supplementary feed and lovingly selected accessories such as blankets, toys and beds. Whether pet shops, animal shelters, vets, breeders, depots or end consumers - everyone benefits from high-quality products, personal service and advice that comes from the heart.

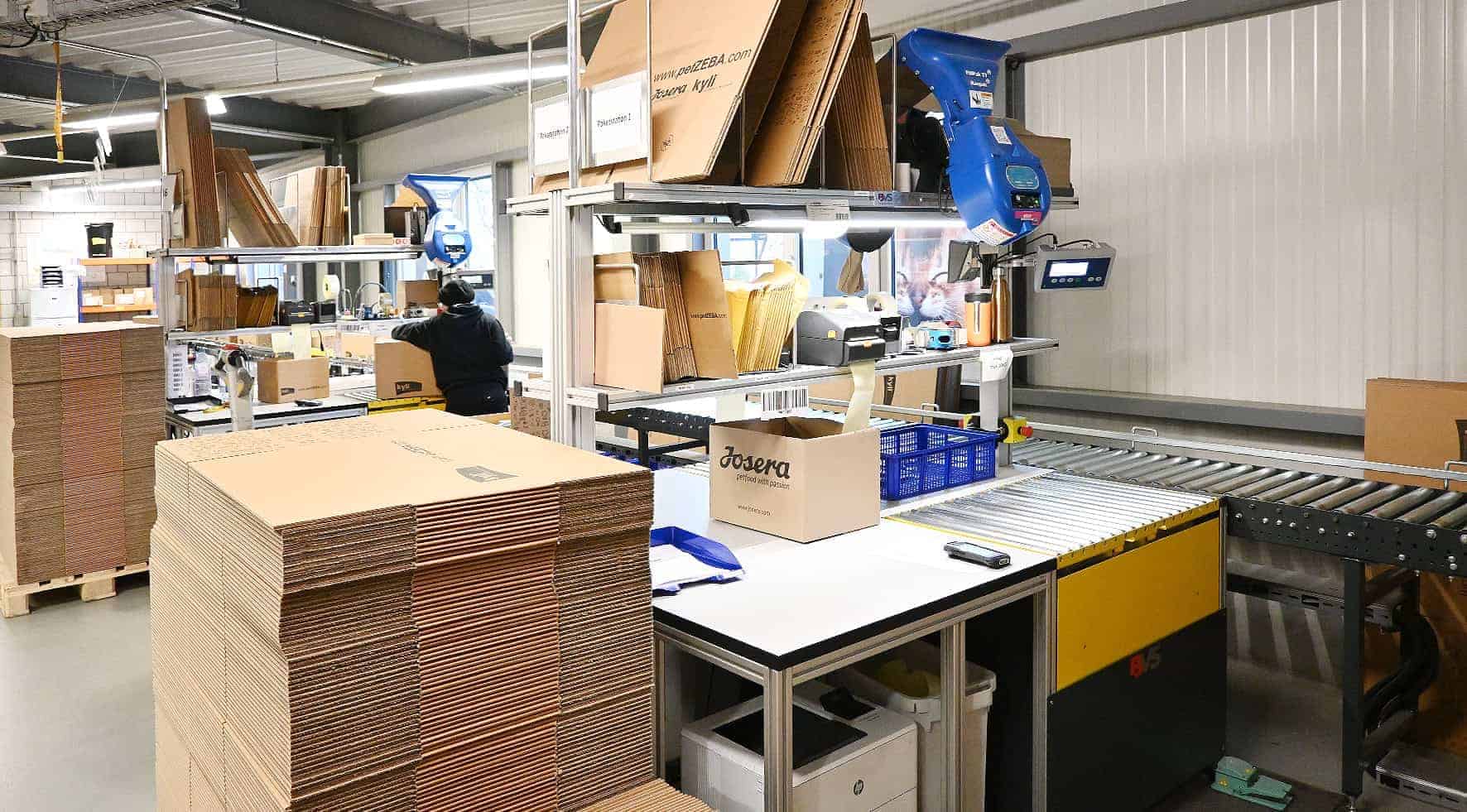

The daily packing work in the warehouse at the Alberswil site was reaching its limits. The existing infrastructure, consisting of two packing stations with short roller conveyors, demanded a lot from the employees. The shipping cartons were prepared by hand and filled and sealed at the packing tables with the goods to be shipped and filling material produced in-house from old cardboard boxes. For space reasons, after six packages had been processed, they had to be stacked before further goods could be packed. The required pallets had to be removed by hand from the free-standing stacks, which meant a great deal of physical strain for the employees. At the same time, there was a lack of space to efficiently store the picked orders temporarily.

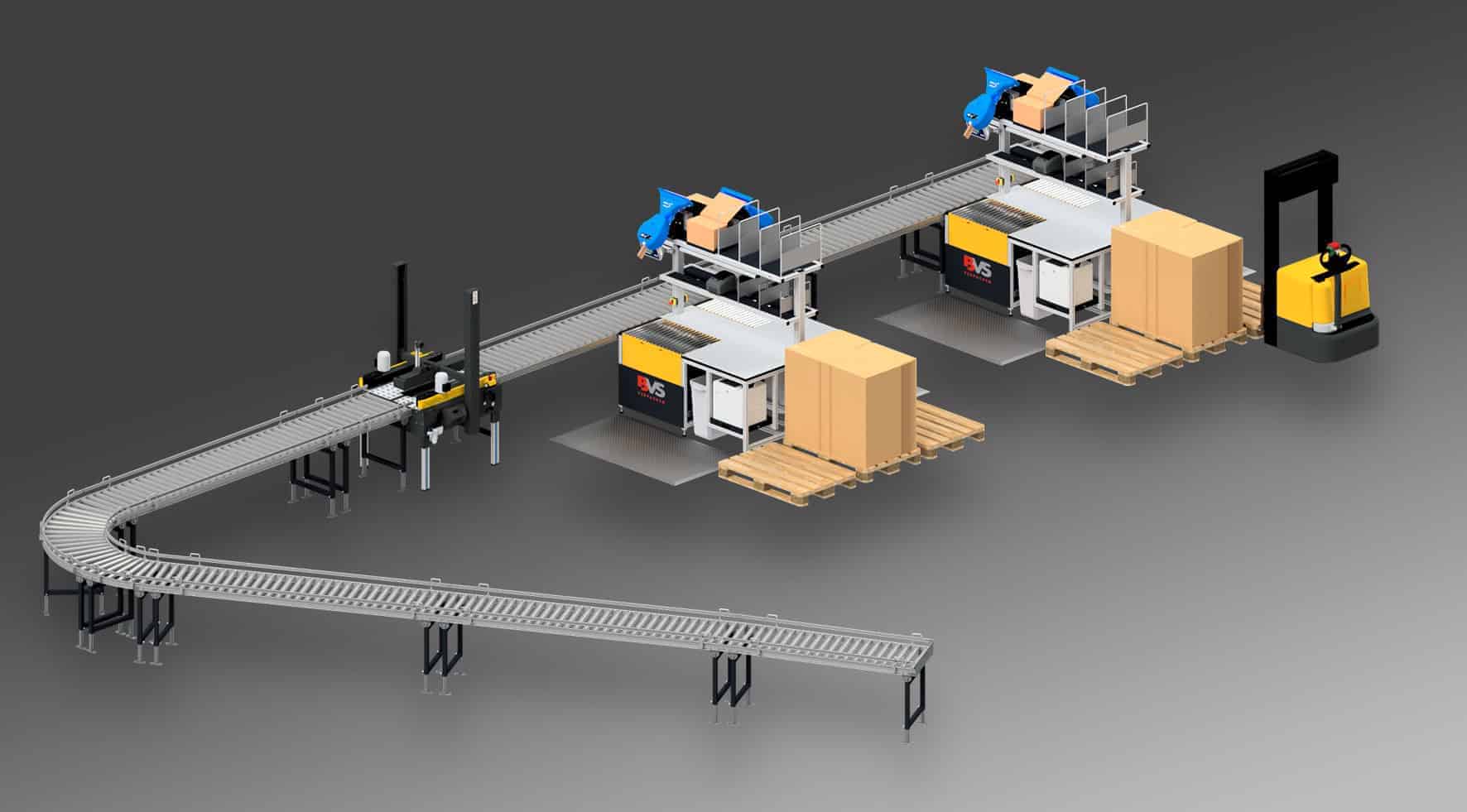

The packaging process was rethought with the aim of "more efficiency, more ease and more enjoyment in daily work" - and the result is impressive:

The innovations have not only simplified processes, but have also noticeably improved the atmosphere in the warehouse. With considerable time savings thanks to fewer walking routes, a significant increase in efficiency and less physical strain on employees, petZEBA and BVS have impressively demonstrated that productivity and ergonomics can go hand in hand.

Packaging - As much as necessary,

as little as possible

BVS uses the NaturePak label for products that enable ecologically sound use, reduce CO2 emissions and generate less waste, regardless of the packaging material used.

Our strategy

Packaging made from recycled paper

Paper pays off for people and the environment in the long term. It is even better to use paper with a high recycled content. Recycled paper optimizes water and energy consumption and thus protects the environment and climate by reducing waste. Recycled paper offers a wide range of added value for all users.

Plastic packaging with recycled content

Polyethylene films are increasingly being produced with a proportion of recycled material, which - as far as technically possible - is being continuously increased. They are the most modern and safest quality packaging for all branches of industry. Due to their low density and excellent physical and mechanical properties, PE films have major advantages over paper, cardboard, metal and glass.

Please select your location: